「誠心誠意」

私たちは挑戦し続けます。

earnestness and sincerity

ミツ精機の製品は、世界の厳しい品質基準を

クリアしながら、高機能・低コストなど

様々な要求にお応えしています。

高度な技術の習得はもちろん、知恵と工夫と

チームワークを磨くため、

人・モノ・コト・技術へ

誠心誠意向き合い、挑戦し続けています。

経営理念

お客様にご満足を頂き、我々は繁栄し、

ロマンの持てる会社にする

常に高度な技術に挑戦し、

時代に即応した製品を生み出す

社会にとって存在価値のある会社にする

代表Message

会社概要

| 社名 | ミツ精機株式会社 |

|---|---|

| 資本金 | 4,950万円 |

| 創業 | 1933年4月 |

| 設立 | 1962年4月 |

| 代表取締役会長 | 三津 久直 |

| 代表取締役社長 | 三津 千久磨 |

| 従業員 | 262名(男性212名/女性50名) 【2025年4月1日現在】 |

| 品質方針 | わたしたちは、品質マネジメントシステムの有効性を維持し、全ての関係者に対し、信頼していただける製品を提供します。 1. コンプライアンスを遵守し、一つひとつの作業をきちんとやり遂げます。 2. 状況や変化を常に把握し、リスクに対する未然防止を計画的に行います。 3. 作業・環境の改善と自らの意識改革で、ヒューマンエラーを退治します。 |

| 主要取引先 | <航空・宇宙機器> 川崎重工業株式会社 住友精密工業株式会社 三菱重工業株式会社 新明和工業株式会社 株式会社島津製作所 ナブテスコ株式会社 株式会社神戸製鋼所 旭化成株式会社 川西航空機器工業株式会社 <その他> 古野電気株式会社 ナブテスコ株式会社 京セラ株式会社 住友重機械イオンテクノロジー株式会社 富士通アイソテック株式会社 住友重機械工業株式会社 |

各種認定

ISO9001:2015の要求事項をすべて含むJIS Q 9100:2016「品質マネジメントシステム-航空、宇宙及び防衛分野の組織に対する要求事項」の審査を受け、適合確認により登録証を取得しております。

規格(初回認証日) JIS Q 9100:2016(2005年11月17日)

登録審査機関 日本検査キューエイ株式会社

登録範囲 航空機用エンジン、装備品及び機体の精密部品の製造

一般産業用機械、装置の精密部品の製造及び組立

(適用外条項:8.3 製品及びサービスの設計・開発)

株式会社ミツ精機 JIS Q 9100

ISO13485:2016「医療機器 -品質マネジメントシステム- 規制目的のための要求事項」の審査を受け、適合確認により登録証を取得しております。

規格(初回認証日) ISO13485:2016(2012年10月10日)

登録審査機関 ビューローベリタスジャパン株式会社

登録事業所 本社・多賀工場

登録範囲 人工関節、人工関節用インプラント部品および手術用器具の精密加工 (適用外条項:7.3 設計・開発)

株式会社ミツ精機 ISO13485

医薬品、医療機器等の品質、有効性及び安全性の確保等に関する法律第23条の2の3第1項の規定により登録された医療機器製造業者であると兵庫県知事により証明され、登録証を取得しております。

登録番号 28BZ200091

登録事業所 本社・多賀工場

有効期間 令和3年9月30日 ~ 令和8年9月29日

本社・多賀工場

〒656-1522 兵庫県淡路市下河合301番地

TEL:0799-85-1133

FAX:0799-85-2602

- バス停

- 「伊弉諾神宮前」より徒歩13分

- 《経路はこちらから》

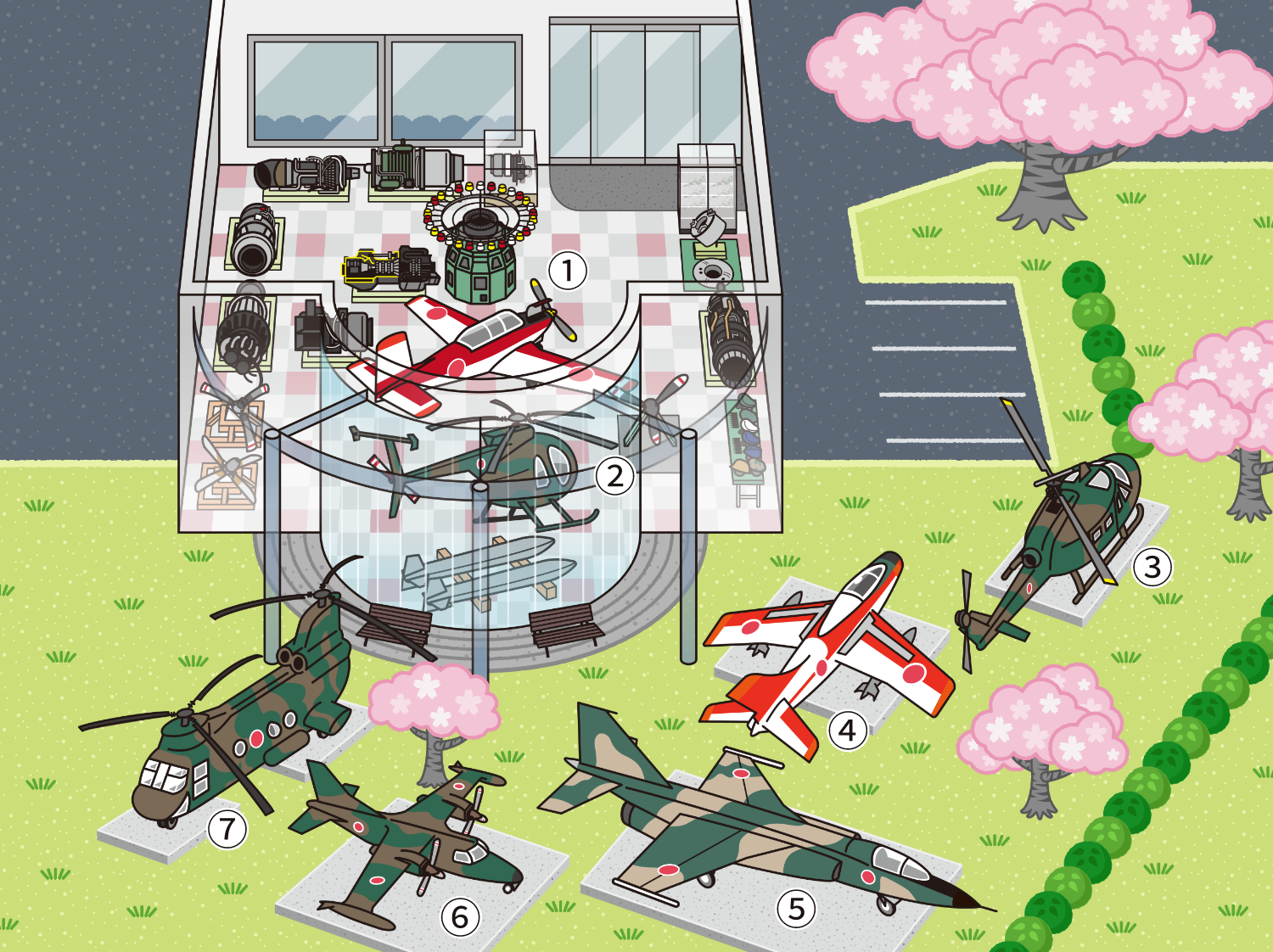

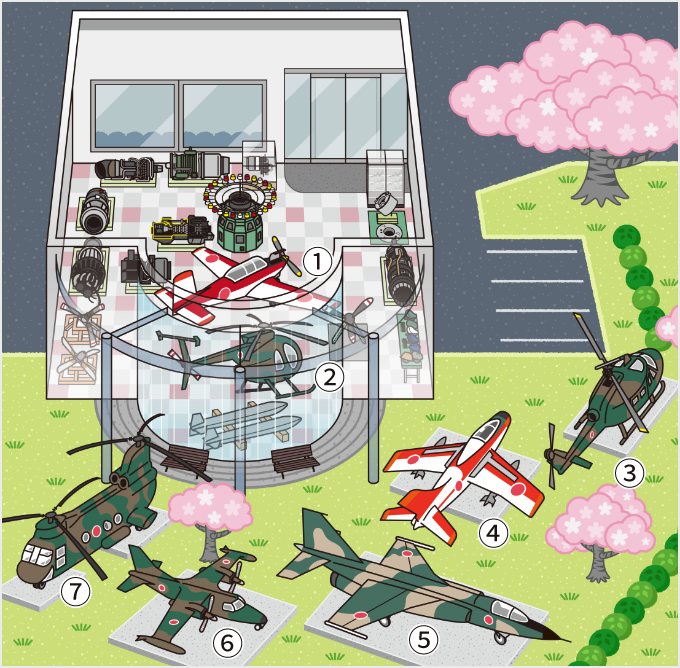

翼の広場

本社にある「翼の広場」では、航空機部品製作における品質向上、航空科学教育の普及、 および航空思想の向上を目的として、自衛隊の航空機を展示し、一般にも公開しています。

【営業時間】

<平日> 9:00~12:00/13:00~17:00

※予告なく営業時間が変更になる場合がございます。

◆団体でのご見学を希望される方

お問い合せページから人数や希望日時などの

情報を送信してください。

① T-3 (練習機)

② OH-6D (観測ヘリコプター)

③ UH-1H (多用途ヘリコプター)

④ T-1B (ジェット練習機)

⑤ F-1 (支援戦闘機)

⑥ LR-1 (連絡偵察機)

⑦ KV-107A (輸送ヘリコプター)

郡家工場

〒656-1511 兵庫県淡路市郡家97番地の1

TEL:0799-85-1313

FAX:0799-85-1130

- バス停

- 「郡家」より徒歩7分

- 《経路はこちらから》

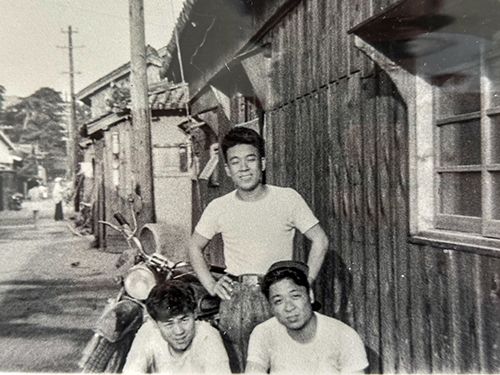

ミツのあゆみ

1933年

大阪市生野区において三津鉄工所創業

1946年

淡路島へ移転。船舶エンジンの製作・修理を開始

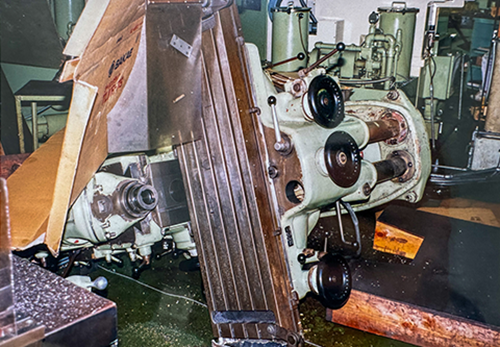

1954年

自動車エンジンを中心とした内燃機関のシリンダー加工を開始

1959年

ニット編機用部品・同付属装置の生産を開始

1962年

株式会社に組織変更

1963年

拡張の為、郡家工場を建設・移転

1965年

社宅を建設

1979年

優良申告法人に指定。航空機部品の生産を開始

1986年

三津鉄工所からミツ精機株式会社に社名変更

1992年

拡張の為、多賀工場(本社、第1・2工場)を建設

1995年

阪神淡路大震災

1996年

医療・福祉機器部品の生産を開始

1998年

明石海峡大橋開通

2001年

多賀工場(第3工場)を増設

2003年

『厚生労働大臣表彰』(技能検定関係)を受賞

2004年

総務大臣より『ふるさと企業大賞』を受賞。

2012年

郡家工場(第3工場)を増設

2016年

兵庫県より『ひょうごオンリーワン企業表彰』『ひょうご仕事と生活のバランス企業表彰』を受賞

2017年

経済産業省より『地域未来牽引企業』に認定

2018年

経済産業省より『健康経営優良法人2018』に認定

2021年

郡家工場(第4工場)を増設

2022年

ひょうごSDGs宣言事業に認定・登録(認定№0008)